Top latest Five waterjet manufacturers Urban news

No heat-impacted zone. Machining solutions like laser cutting and EDM heat the fabric along with the parts will have to be heat taken care of all over again soon after machining. Waterjet Lower pieces retain their warmth procedure when cut. Because of this you can begin with pre-warmth treated product and keep the prices down.

CNC 7.14mm abrasive head waterjet cutting spare parts price tag mixing tube concentrating tubes water jet Nozzle Orifice manufacture

In abrasive cutting, the process mixes a hard, powdery product in the water jet. Resources including garnet or corundum are used as abrasive brokers.

Because of the angles which can be cut, component packages may need to own supplemental cuts to cost-free the part with the sheet. Attempting to slide a fancy component in a extreme angle from the plate could be difficult devoid of suitable aid cuts. See also[edit]

An abrasive jet operates similar to a pure waterjet, except in the event the stream of water exits the orifice, an abrasive compound including garnet mixes Using the stream.

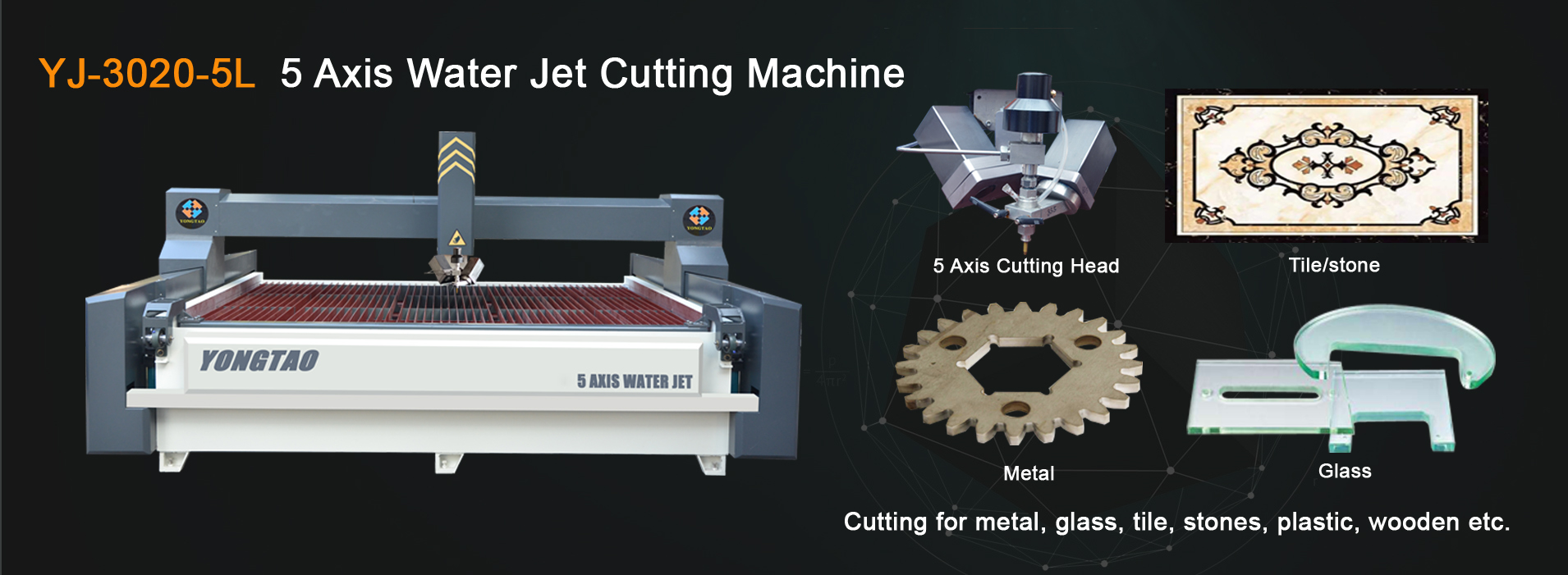

A 5-axis cutting head may be used to chop four-axis components, where by The underside surface area geometries are shifted a particular sum to generate the appropriate angle and also the Z-axis continues to be at just one top. This may be helpful for applications like weld planning where by a bevel angle needs to be Lower on all sides of a part that could later on be welded, or for taper compensation functions in which the kerf angle is transferred to the squander material – thus eradicating the taper usually found on water jet-cut parts.

With waterjet for sale the potential to chop from many different types of elements which includes metallic, aluminum, steel, plastic and wood, you are able to change your models into genuine usable pieces and products.

The brand new and enhanced INFINITY waterjet cutting series is our created to past flagship collection which is well suited for big locations. The INFINITY waterjet cutting technique gives specific cutting of additional-huge sheets ranging from ten ft. to thirteen ft. broad by providing desired, which permits mass production and cutting of enormous elements.

The advantage of obtaining individual cutting heads on completely unbiased Z-Carriages is the liberty the operator will get to position the heads as close or as considerably apart as sought after in seconds.

TCI Precision Metals waterjet cutting is environmentally friendly and sustainable. water jet cutter Waterjet generates a lot less scrap, works by using fewer electric power than regular cutting strategies, and the water and garnet utilized for cutting is totally recycled.

A cutting head mounted to the lightweight crossbeam will be able to accelerate faster involving cuts which will boost Total efficiency.

WAZER's Experienced-quality waterjet can Slash any water jet cutter materials for on demand manufacturing of custom parts. WAZER is perfect for on-web-site fabrication and prototyping initiatives.

In comparison to other cutting processes that use warmth, mechanical pressure or plasma torches, water-jet cutting is an extremely gentle and exact cutting method. The silky-sleek Minimize edges demand no transforming along with the kerfs from the water jet cutter for sale high-quality water jet are minimum.

IGEMS also provides an advanced and easy to use 3D software package for five-axis cutting with Beveljet sixty® and WJA FiveX machines. Together with the 3D software water jet cutting machine program – IGEMS 3D5X – it is an easy method to produce toolpaths on 3D designs from Action and IGES information. Straightforward to discover and convenient to use and rapidly to run ...